When it comes to managing and protecting wires and cables, especially in industries like automotive, aerospace, and electronics, using the right type of wire protection is crucial. Two common options are wire loom and braided wire loom, both serving similar purposes but with distinct differences. Let's delve into what sets them apart and which might be the better choice for your needs.

A wire loom, also known as a cable loom or conduit, is a flexible tube typically made of plastic or corrugated tubing. Like our Wire Loom Tubing, its primary purpose is to protect and organize wires and cables, preventing tangling, abrasion, and damage from environmental factors such as moisture, heat, and chemicals.

Key Features of Wire Loom:

1. Material: Wire looms are commonly made from materials like polyethylene (PE) or polypropylene (PP). These materials offer decent flexibility and resistance to abrasion and most chemicals.

2. Flexibility: Wire loom is quite flexible, making it easy to bend and route around corners or through tight spaces.

3. Installation: It's relatively easy to install a wire loom – wires are inserted into the loom, and the loom can be secured with various fastening methods like clips or ties.

4. Protection: While a wire loom offers protection against minor abrasions and environmental factors, it may not be as robust in extreme conditions compared to a braided wire loom.

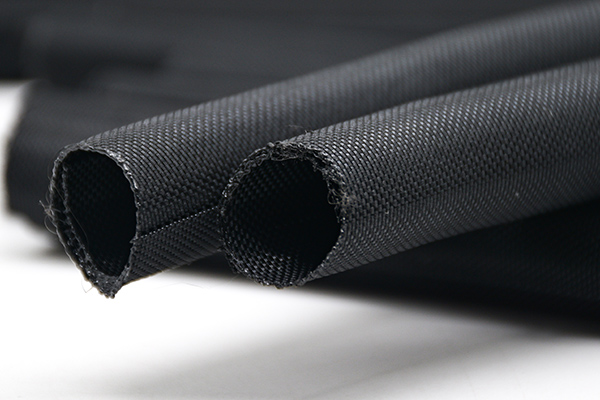

A braided wire loom, also known as expandable wire sleeving, is a woven mesh tube designed to provide a higher level of protection and support compared to a standard wire loom.

Key Features of Braided Wire Loom:

1. Material: A braided wire loom is typically made from materials like polyester, nylon, or fiberglass, which offer greater strength and durability compared to a plastic loom.

2. Flexibility: Despite being more robust, the braided wire loom remains quite flexible, allowing for easy installation and routing of wires.

3. Abrasion Resistance: The woven construction of braided wire loom provides excellent protection against abrasion, making it suitable for applications where wires are subjected to frequent rubbing or movement.

4. Heat Resistance: A braided wire loom often offers better heat resistance compared to a plastic loom, making it ideal for applications where wires are exposed to high temperatures.